As an engineering, consulting and strategic manufacturing company in the heavy mobile equipment space, we are committed to solving the puzzles our customers bring to us. Tackling equipment and software challenges is fundamental to the success of our engineered designs and our business.

The applied heavy mobile equipment innovation we are able to deliver rests on our close engagement with customers. To listening first and foremost, and then by working in partnership, being open-minded, creative, and yes, smart enough, to develop and implement the solutions that help you succeed.

Here’s what’s new:

- The RodBot Marches On, the RaisePro Emerges

- Hybrid Electrification Excellence-in-Action

RaisePro-48T ITH: Sudbury Basin Drilling

MEDATech Borterra’s RaisePro-48T In-The-Hole Raise Drill has been put through its paces in the Sudbury basin – and exceeded expectations. The seasoned operators from Boart Longyear Drilling Services utilized the RaisePro in extremely challenging ground conditions to drill a 42” diameter backfill hole at Vale’s Copper Cliff North Mine.

The RaisePro was developed in collaboration with Archer Mining and Civil Services for best-in-class mobility, productivity and safety, specifically for large-diameter drilling applications. Stay tuned to our LinkedIn and Instagram channels for more updates on this exciting, truly new and novel tool for the mining industry in Q4 2025.

RodBot Continues to Evolve

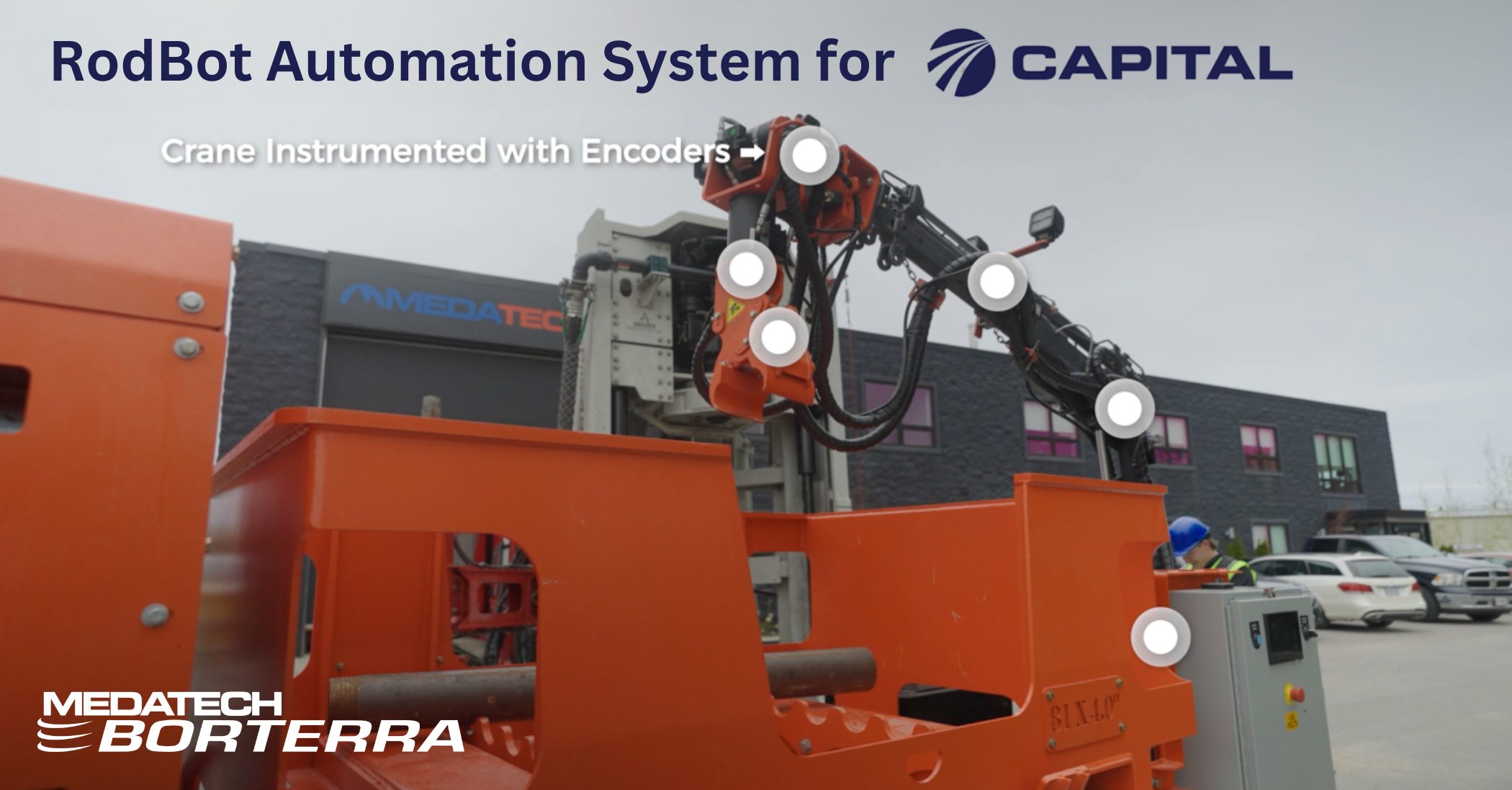

RodBot, from our Borterra Specialty Drilling Solutions division, eliminates manual handling, one of the most dangerous jobs in drilling. Automated rod handling is where the industry is going, so we continue to develop and support RodBots in the field across several industrial verticals, from mining to renewables.

Just recently, we integrated the first-ever RodBot Automation System on a Sandvik DA201/101 rod handler for Capital Limited. Next up: an in-house–designed underground rod handler, purpose-built with flexible configurations for both ITH and Diamond Core drilling.

Hybrid Electrification Excellence-in-Action

For our AltDrive division, now a decade-plus into its existence, we continue to closely support a customer’s trailblazing hybrid electrification of their oilfield service rigs, which use the original diesel engine as a battery generator for work that takes place off-grid. The rigs average 1.5 hours’ diesel run time per 8-hour shift.

We are actively pursuing this exact type of hybrid electrification for other industrial applications of heavy mobile equipment in remote (i.e. far-from-grid) settings, where you have the same challenges of range extension as well as intermittent peak power versus baseload power demands. Hybrid electrification is the answer to both questions. We see great opportunity to solve the same problem in other industries.

Designing or Upgrading Mobile Equipment?OEMs and end users turn to MEDATech for accelerated mobile equipment development. We have been acting as an outsourced R&D departmentfor vehicle software solutions and builds since 2003. If you have an idea, WE CAN MAKE IT HAPPEN.We would love to hear from you! Simply reply to this email. ~ The MEDATech team