Customer: RESEMIN – Peru

About The Project

Peru-based RESEMIN sells underground mining drilling equipment around the globe, specializing in narrow vein mining machines. With an eye to the future, the team at RESEMIN determined to begin electrifying their equipment lineup, starting with a battery-electric (BEV) version of their popular Troidon 55 XP jumbo.

RESEMIN chose MEDATech on the strength of our 10+ years of electrification work in the underground mining sector. The project involved designing a complete AltDrive system to suit the vehicle, supplying major drivetrain components, commissioning the narrow-vein underground jumbo on site in Peru, and validating real-world performance—without a lengthy feasibility phase, and on a fixed-cost program with an aggressive timeline.

Solution

The jumbo needed to be able to tram on battery power, and drill while tethered. The prototype called for an interlock that prevented drill operation unless plugged in.

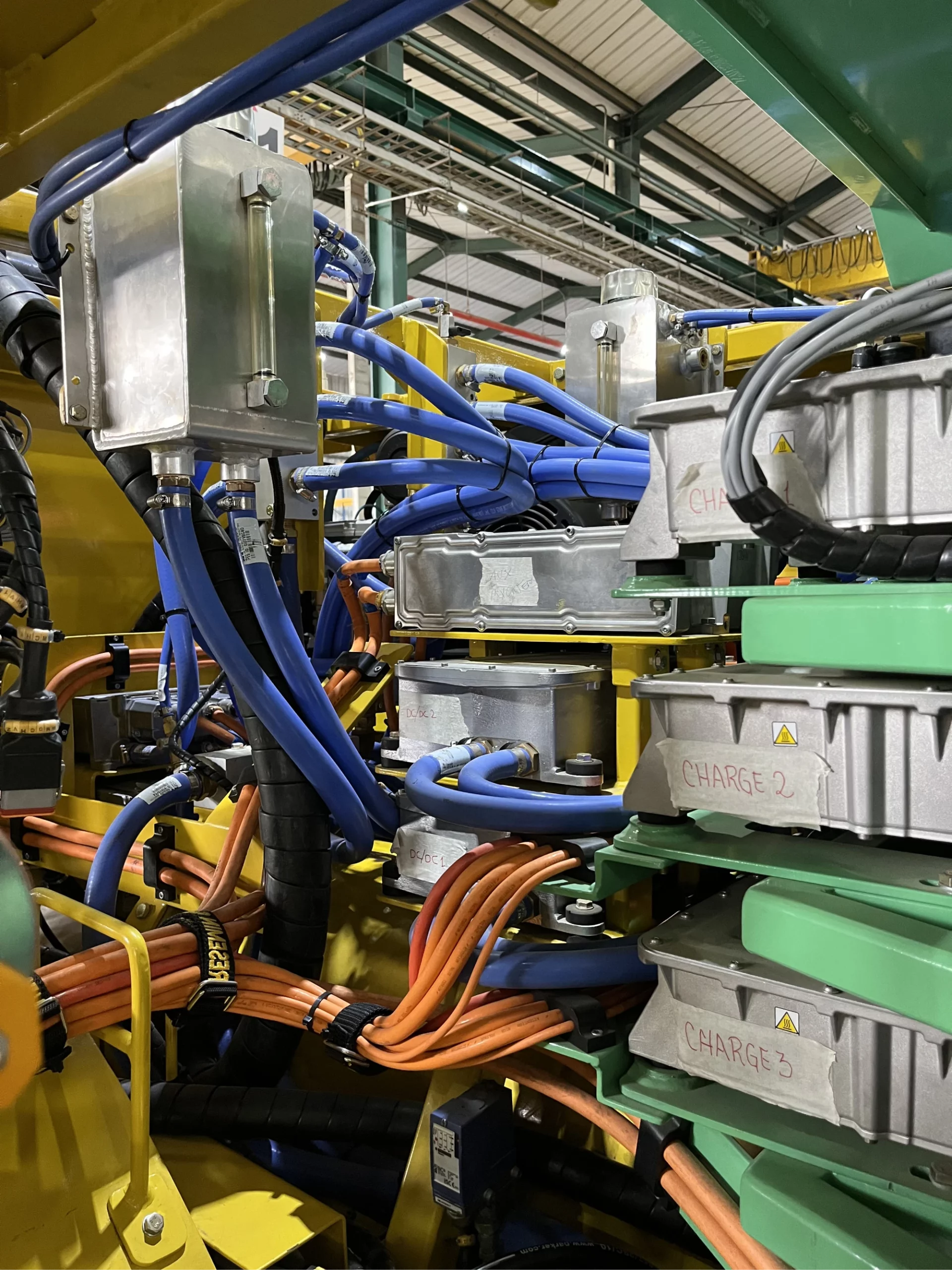

MEDATech provided the end-to-end BEV system design and all major drivetrain components including batteries, power electronics, and controls. Since the BEV Troidon 55 XP is intended for use anywhere in the world, MEDATech engineered a voltage-agnostic base electrical architecture.

The RESEMIN team and a local engineering partner handled mechanical mounting and installation. MEDATech engineers then travelled to the RESEMIN factory in Lima, Peru for six weeks to oversee the power-up, load software, and conduct field commissioning and fine tuning.

Key software features included:

- Hill-holder for safe tramming

- Regeneration control for energy recovery

- Hydraulic optimization for drilling operations

- Telematics for performance data and remote diagnostics

Throughout the project, MEDATech coordinated closely with RESEMIN’s engineering leadership while navigating language barriers, differing business cadences, and schedule pauses on the customer side that extended the timeline.

Results

At the tuning/ commissioning phase, the MEDATech AltDrive team achieved the precise drilling control and smooth drivability we had targeted. Field trials confirmed that the prototype performed in line with expectations, to RESEMIN’s strong satisfaction.

Early outcomes included:

- Higher power & improved drilling precision through software-driven controls and hydraulics tuning.

- Much lower noise, heat and vibration, yielding a drastically quieter cab environment and cleaner air at the face.

- Standardization of components such as pumps for all power scenarios, as the AltDrive system standardizes voltage and frequency for AC motors.

- True mobility through untethered battery tramming to and from headings, with tethered drilling, downslope regeneration and opportunity charging during the duty cycle.

- Path to commercialization is clear, with remaining items limited to technical refinements. The BEV platform positions RESEMIN to introduce a BEV jumbo to its product line in the near future.

With a successful prototype underway, RESEMIN is considering expanding electrification to additional models, leveraging the same controls architecture, telematics, and commissioning model.

Services Provided

Highlights

- Converted a narrow-vein jumbo to battery-electric (BEV)

- Advanced controls: hill-holder, operator regen control, hydraulic optimization

- Operator benefits: less noise, heat and vibration; cleaner air

- Met performance goals; roadmap to further product line electrification