Engineering Services Menu

Heavy-Duty Equipment Innovation

Advancing Mobile Equipment Design

MEDATech (Mobile Equipment Design & Automation Technology) is in the

business of innovation. We solve design problems, improve efficiency, build software solutions and leverage data-driven intelligence. Our Engineering Services division provides OEMs and end users with custom solutions for their heavy-duty mobile equipment needs.

A History of Innovation Engineering

MEDATech Engineering Services Limited has been designing, building and

upgrading industrial mobile equipment, as well as software solutions, for

customers around the globe since 2003.

Accelerating Product Development

We succeed, quickly – where others don’t – because of our teams. Our engineers, technologists and skilled shop mechanics; our hydraulics team; our electrical engineering & software team; our robotics controls team; and our talented field service team. Because we work so closely together,

nothing is lost in translation.

Together we upgrade existing machines, plan and build brand new mobile

equipment, and create advanced software and control systems. We work closely together with you to achieve your project’s objectives. We accelerate product development across industries including Mining, Oil & Gas, Construction, Defense, Energy and Transportation. Got an idea? We can make it a reality.

Customers Across Industries

Why Choose MEDAtech?

Advanced Skills, Tight Teamwork

Whether it’s a vehicle upgrade or ground-up build, MEDATech is unmatched at completing work quickly and

correctly. Our teams (software, mechanicals, automation / robotics controls, hydraulics, electrical and service) work very closely together to achieve objectives.

Longstanding Customer Relationships

A handful of MEDATech clients have been working

with us for 10, 20+ years. Why? Because the question for us is always the same: is there a way we can make this even better?

Global Reach

We tackle projects for customers on four

continents. When you need commissioning, service or

modification, our team is on its way.

1. Mechanical Structural Design & Build

Ground-up builds can include vehicle frame/chassis construction with 3D modelling and FEA materials evaluation; Hi-Fi Battery-Electric Vehicle (BEV) Simulation; drive systems; tires/tracks; all controls, systems and interfaces.

2. Control Systems, Software & Automation

Control systems are the brains of every machine. We design Vehicle Management Units

(VMUs), Human-Machine Interfaces (HMIs), battery Temperature Management Systems (TMSs), and software systems that do everything from controlling our sophisticated automation packages to modelling and monitoring full-site energy usage. We also build secure telematics systems that transmit CAN network data for diagnostics, remote control and other functions.

3. Hydraulic & Fluid Systems

Our engineering-first approach optimizes hydraulic and fluid systems for performance. We deliver precise, low-maintenance designs for tough environments that are validated virtually before parts are ordered.

4. Electrical Design Capabilities

Capabilities include high voltage panel design,

AC/DC electric systems, low/high voltage

distribution panels, harness design, installation

& assembly, and serial communications such as

CAN bus & ISOBUS.

5. Hybrid & Electric Drivetrain

Many of our vehicles are battery electric, but hybrids offer a strong step toward decarbonization. Diesel/battery-electric hybrids reduce fuel use by 30–50%+. A smart choice for fleets transitioning to full electrification.

Feasibility Studies & Consulting

Feasibility Studies & Consulting

Feasibility in action: OPG evaluates hybrid power for next-gen transporters. We assessed system complexity, efficiency, and suitability. Battery options—lead-acid, Ni-MH, sodium-ion, and lithium-ion—were compared on energy density, cycle life, cost, and safety. Electric motor and electronics suppliers were vetted for hybrid system fit.

Challenge

Ontario Power Generation (OPG) needed to upgrade its diesel-powered transporter fleet to meet Tier 4 emissions standards and reduce indoor noise in nuclear facilities. They sought guidance on drivetrains, batteries, and system specs for future procurement.

Solution

We assessed EV and hybrid architectures, evaluating system complexity, efficiency, and suitability. Battery options—lead-acid, Ni-MH, sodium-ion, and lithium-ion— were compared on energy density, cycle life, cost, and safety. Electric motor and electronics suppliers were

vetted for hybrid system fit.

Results

The feasibility study clarified drivetrain options and trade-offs, leading to OPG’s decision to adopt a Gen 4 transporter that surpasses emissions requirements

and supports long service life. The study reinforced OPG’s leadership in low-emission nuclear logistics and

shaped future procurement strategy.

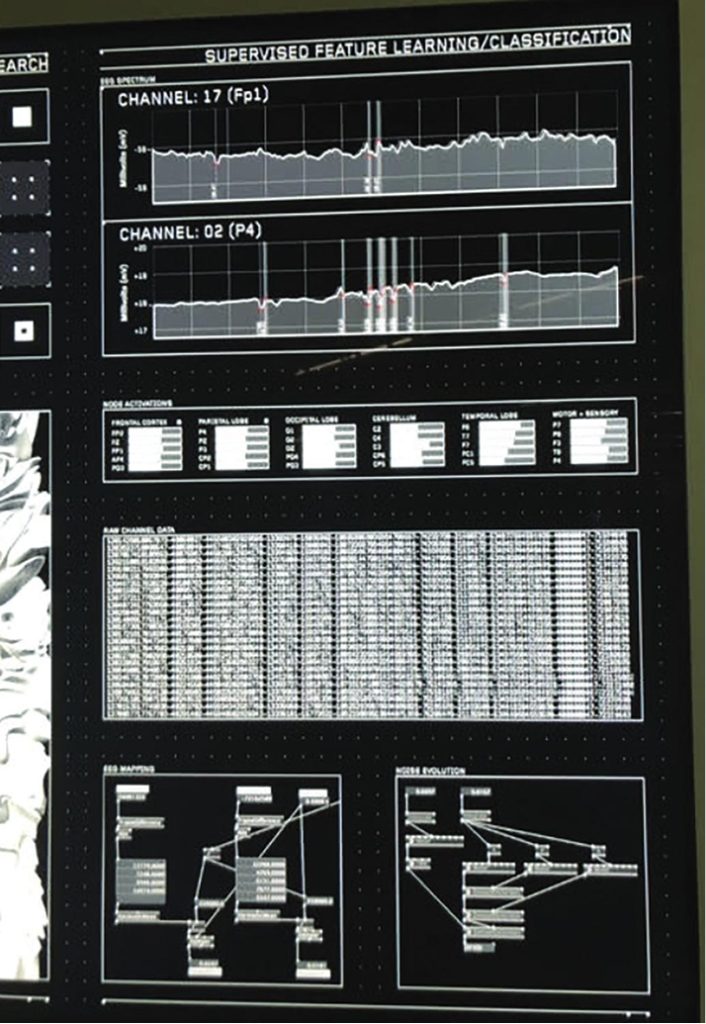

Vehicle Control Systems & Software Development

Control Systems & Software

MEDATech designs control systems including Vehicle Management Units

(VMUs) such as the AltDrive VMU— central to hybrid and EV powertrains.

VMUs integrate drive, steering, and charging logic. We also build and

integrate CanBus networks, GPS, automation, TMS, HMIs, and telematics,

which enable secure wireless transmission of CAN-network data,

essential for diagnostics, efficiency analysis, and gathering site-specific

data—like geotechnical info from drills.

Software Development

Modern EV and heavy-duty systems rely on smart software to manage

sensors, drive logic, operator interfaces, and data logging. MEDATech creates custom code for vehicle functionality, like the autonomous RodBot™ material handler.

Packaged Solutions

Fleet Feasibility Studies simulate total fleet energy use, battery sizing,

charging infrastructure, and cost— comparing BEV and diesel fleet

efficiency.

MEDAData™ logs CAN-bus data, fault codes, and operator inputs to power

predictive maintenance and analytics, with dashboards and event logs.

MEDATech software isn’t off-the-shelf—it’s engineered for the grey area of

operational nuances. Model-based development ensures consistent,

standards-based code that’s been proven in the field, managing EV fleets

across mines and heavy-industrial sites.

World’s First On-Highway Battery-Electric Haul Truck

MEDATech’s AltDrive-equipped Western Star 4900XD hauls concentrate at Highland Valley Copper mine, B.C

In a mining industry first, MEDATech converted a Western Star 4900XD into a battery-electric haul truck for Teck Resources. Since 2022, it has transported concentrate from Highland Valley Copper mine to a rail terminal in B.C. powered by the MEDATech AltDrive system.

135 km range with modular battery swap

418 tonnes of CO2 reduced annually

Quieter, smoother, lower-maintenance

Regenerative braking. Zero tailpipe emissions.

Challenge

Teck aimed to decarbonize a 46 km round-trip concentrate haul without sacrificing performance or uptime, in line with sustainability goals.

Solution

MEDATech equipped the truck with its AltDrive electric drivetrain. The vehicle delivers 135 km range, regenerative braking, and hot-swappable battery packs.

Results

Nicknamed the ‘Teck Truck,’ it avoids 418 tonnes of CO₂ emissions annually. It runs quietly with lower maintenance, strong regenerative braking and more power than a diesel.

Hybrid Retrofit Modernizes Oilfield Workover Rigs

Watson Hopper’s diesel-electric hybrid conversion delivers better production, efficiency and much more

Once Colorado-based Watson Hopper partnered with MEDATech, it was able to offer a hybrid diesel/battery-electric retrofit that outperforms diesel workover rigs while cutting noise, fuel use, and emissions.

• Hybrid retrofit: power, efficiency, safety

• Fuel savings + carbon reduction

Challenge

Conventional rigs rely on diesel engines running even when stationary for days. Operators needed a solution that worked in remote areas without grid access.

Solution

A MEDATech Feasibility Study showed hybrid was the best fit. The diesel engine acts as a generator, while batteries power the drive system, hydraulics, and a

powerful winch motor. When grid power is not available, diesel run time averages 1.5 hours per 12-hour shift.

Results

The first hybrid rig went from design to delivery in just over a year. With two now operating, Watson Hopper has ordered four more. Operators report faster, more

precise winching, quieter operation and low fuel costs.

One Rig Tackles Four Underground Drilling Tasks

The RaisePro-48 In-The-Hole drill brings game-changing versatility, safety, and efficiency to underground mining

MEDATech’s RaisePro-48T, unveiled at MINExpo 2024, brings unmatched

versatility to underground mining. This track-mounted ITH raise drill handles production bores, service holes, slot raises, and manways—all in one unit—improving safety, precision, and productivity.

One rig covers 4 drilling functions, 3.5” to 48” holes

Increased safety

Reduced capital and maintenance costs

Challenge

Underground mines have needed multiple drills for different hole sizes (3.5” to 48”), driving up costs,

complicating logistics, and increasing risks during rig swaps.

Solution

MEDATech Borterra developed the RaisePro-48T to handle 3.5”–48” holes with 360° reach. Equipped with a top-drive mast, it delivers power for raise-boring and fast production. Features include CAN-BUS modular controls, remote operation, rod presenter, and optional RodBot for safe, automated pipe handling.

Results

A trial at Vale’s North Mine in Sudbury saw RaisePro replace four rigs with one, simplifying operations. Full reach, remote control, and automation also reduced operator exposure and increased efficiency.

Hybrid Dual-Mode Drill Boosts Dam Remediation

MEDAtech WS6000 enhances accuracy and efficiency for Alabama Power’s dam program

Stabilizing embankment dams involves injecting cement into bored holes to

reinforce subsurface rock. To improve safety and speed, Alabama Power

adopted the WS6000 Hybrid Water/ Sonic Drill, which combines sonic and

water-hammer technologies in one rig.

Two drilling technologies in one rig

RodBot automates rod handling

Live geotechnical and rig data

Faster cycles, greater precision

Challenge

At Alabama’s Logan Martin Dam, remediation required accurate drilling through overburden and karst. Traditional methods relied on two rigs and multiple setups—slowing work, increasing risk, and reducing accuracy.

Solution

MEDATech engineered the WS6000 to integrate high-frequency sonic and high-pressure Wassara water-hammer drilling in a single top-drive unit. Operators switch modes instantly. The track-mounted rig features RodBot, which increases safety by automating rod and casing handling. The rig also transmits data for remote diagnostics and geotechnical insight.

Results

The WS6000 improves drilling speed and precision. Dual-mode drilling minimizes deviation, while RodBot

improves crew safety. Remote monitoring enhances performance and reduces downtime.

Optimizing OPG’s Nuclear Waste Transport Fleet

Comprehensive assessment, overhaul and maintenance program boosts safety across Ontario Power Generation sites

In 2005, Ontario Power Generation (OPG) enlisted MEDATech to upgrade

its nuclear waste transporter fleet—targeting defect elimination, condition monitoring, and preventive maintenance to meet nuclear safety

standards. MEDATech still supports system upgrades and lifecycle

management today.

Reduced downtime, better safety

Unified maintenance across sites

Evaluation model meets nuclear safety standards

Challenge

Transporters at three OPG sites suffered from hydraulic failures, CAN- bus errors, and mechanical flaws. No

standardized maintenance plan led to unplanned downtime and safety risks.

Solution

MEDATech conducted a full fleet health assessment to identify failure patterns, then implemented a lifecycle strategy for all transporter models: preventive

maintenance, condition monitoring, and a unified spare parts system. A custom evaluation matrix aligned with

nuclear safety and reliability standards.

Results

Reliability improved fleet-wide. MEDATech’s protocols are now part of OPG’s procurement standards, a key

element of its long-term modernization plan. Ongoing support and system upgrades continue.

Monorail System For High-Efficiency Mining

Re-engineering underground mining: MEDATech and Torex Gold pioneer the Muckahi System

Torex Gold partnered with MEDATech to revolutionize underground mining on steep terrain using a compact monorail system within narrow tunnels.

Successful trials at 30° gradients

30% capex/opex savings

95% GHG reduction

50% tunnel size reduction

Challenge

Move ore, equipment, personnel, and tailings efficiently through steep, confined tunnels (up to 30° incline)

while meeting a target of 7,000 tonnes/day.

Solution

Together with mining equipment innovator Fred Stanford, MEDATech developed the Muckahi Mining

System—a ceiling-mounted electric monorail supporting drilling, mucking, scaling, conveying, and personnel

transport. The system uses battery-electric locomotives to navigate 4m×4m tunnels with ease. MEDATech

built or adapted all equipment.

Results

At Torex’s El Limón-Guajes site in Mexico, Muckahi proved effective on 30° slopes, streamlining ore transport and mining operations. It nearly doubled projected IRR and accelerated cash flow by 60–80%, with up to 95% GHG reduction and minimal ventilation

needs.

Battery-Electric Motor

Grader Retrofit

Decarbonizing road maintenance: MEDATech and Borden Gold innovate with a battery-electric retrofit

For Borden Gold to meet their goal of opening the first all-electric

underground mine in Canada, they needed to convert a number of

machines from diesel to battery-electric. The miner selected MEDATech

to convert a Caterpillar 12M3 grader into a fully battery-electric machine for underground mining.

First battery-electric grader underground

8-hour runtime, 300 kWh battery

Zero tailpipe emissions

Matches diesel performance

Reduced noise & ventilation

Challenge

Replace a diesel-powered grader with a zero-emission alternative without sacrificing performance or range in

underground environments.

Solution

MEDATech retrofitted the 12M3 with a 300 kWh battery and dual-motor electric drive. The battery-electric grader matches diesel performance and grading force, with up to 8 hours of runtime. All components— battery, controls, and drivetrain—were integrated into the original chassis without structural changes.

Results

The grader was deployed at Borden Gold, marking the first known battery- electric retrofit of a motor grader

underground. The project cut GHG emissions, noise and ventilation needs while maintaining diesel-equivalent

performance.

Truck Mounted Auger Drill

Breaking new ground: the first highway-legal, truck-mounted 12-foot diameter auger drill, for Hydro One

In 2010, Hydro One asked MEDATech to build a truck-mounted auger drill for transmission line expansion.

First highway-legal 12′ truck-mounted auger

140,000 ft-lb custom rotation drive

Smart “return to centre” function

Fully certified for Ontario roads

Challenge

Design a mobile auger capable of drilling holes up to 12 feet in diameter and 60 feet deep—while staying road-

legal in Ontario. No 12′ drill had ever been mounted on a highway-legal truck.

Solution

We built a custom drill on a Kenworth T800 chassis, with a 140,000 ft-lb rotation drive powered by dual radial piston motors and a single-reduction gearbox. A CAN-BUS control system enabled touch-screen smart

functions, including a “return to centre” command.

Results

Delivered in under 18 months, the drill weighed under 100,000 lbs—meeting highway limits as well as performance targets across the new 200 km line.

DESIGNING OR UPGRADING MOBILE EQUIPMENT?

LET’S GET YOU ON THE FAST TRACK.

OEMs and end users turn to MEDATech for accelerated mobile equipment development. We have been acting

as an outsourced R&D department for vehicle software solutions and builds since 2003. If you have an idea,