Engineering Services Menu

Material Handing & Robotics

There was a time when everything was done by hand. The ancient Egyptians gained an advantage with the use of long levers, and the ancient Greeks multiplied that advantage with the block and tackle.

Since then, innovations blossomed and today machines accomplish all material handling in certain projects. Walk down any auto assembly line and you’ll see as many robots completing tasks as humans. That’s because automating material handling saves time, increases safety and reduces human error.

Robotics

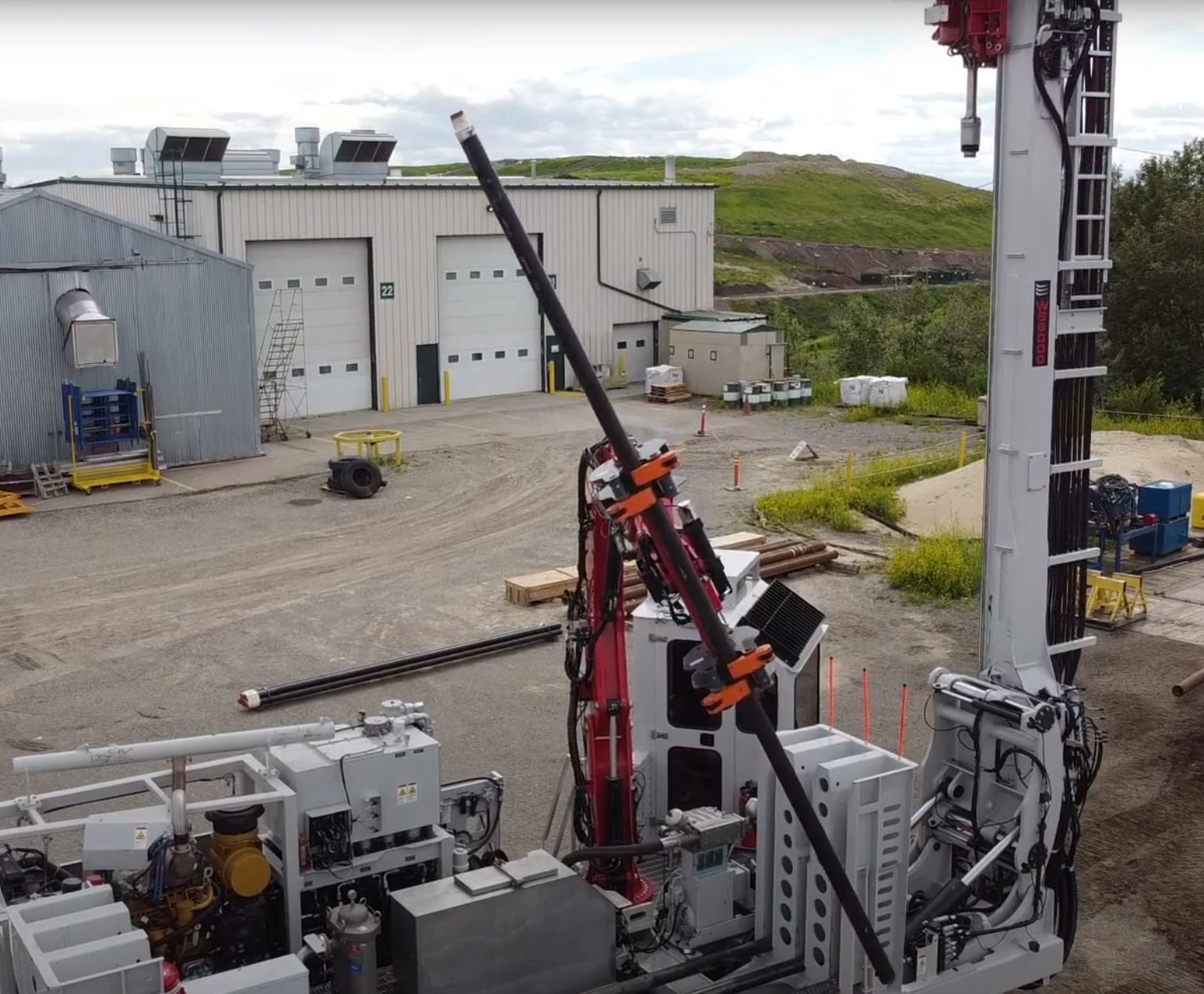

Borterra is leveraging advanced AI vision systems to take automation even further – enabling fully autonomous rod and material handling for heavy-duty applications. Our AI-enabled RodBot uses real-time visual detection and navigation to identify, prioritize, and manipulate individual drill rods without the need for human intervention.

This technology increases safety by keeping operators clear of hazardous zones, boosts productivity through intelligent path planning, and delivers consistent, repeatable performance across varying conditions. Designed and built in-house, these intelligent systems are fully customized to your equipment and site needs, offering a turnkey solution for high-performance, hands-free operation.

Material handling & robotics, at your service

MEDATech develops and builds automation and robotics components, integrating them into the machines we create as a matter of course. We write all the code and do all the building in-house. If you have a repetitive process that’s inefficient, unsafe or both, we can perform a full-system design to automate that process. That includes user path planning, collision avoidance, and other parameters.

Whatever materials-handling problem you might have, we would be happy to explore it with you. To find out more, please contact us using the form below.